In modern day commercial and domestic buildings, electrical systems are the backbone of operations. Yet too often, they’re only given attention when something goes wrong. Preventive maintenance, particularly through electrical testing, changes that mindset. It ensures equipment health, prevents costly failures, and safeguards both people and assets. In this blog, we’ll explore why electrical testing should be at the heart of any preventative maintenance strategy.

Protecting People & Property

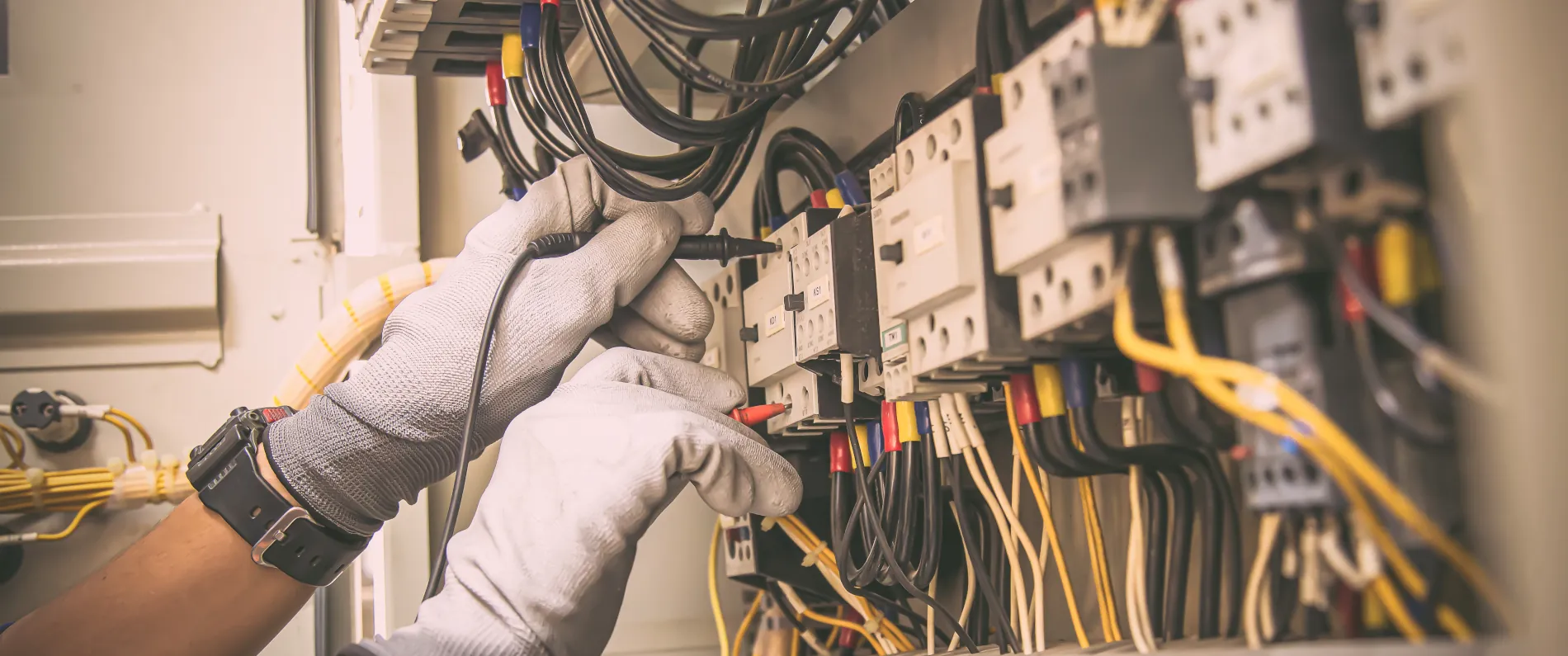

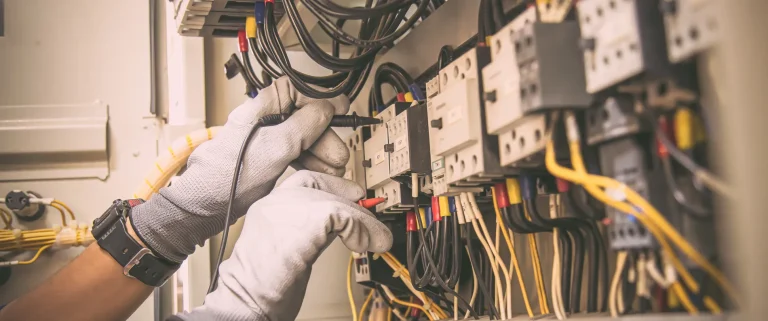

Electrical faults don’t just interrupt operations. In fact, they pose significant risks to both human life and critical infrastructure. Hidden issues such as loose terminations, deteriorating insulation, or undetected wiring defects are leading causes of electric shock, arc flash incidents, equipment and electrical fires. Therefore, proactive testing brings these vulnerabilities to light long before they escalate into dangerous or costly events. Key electrical tests that help safeguard your property include:

- Insulation resistance testing identifies moisture ingress, thermal stress, or material degradation in cables and windings, allowing for timely replacement before catastrophic failure.

- Infrared thermal imaging detects abnormal heat patterns in panels, switchgear, and connections. This often reveals overloaded circuits or loose joints invisible to the naked eye.

- Ground resistance testing verifies that current faults have a reliable, low maintenance path to earth. Therefore, reducing the likelihood of shock hazards and ensuring protective devices trip as designed.

By systematically uncovering hidden defects, electrical testing shifts maintenance from reactive firefighting to proactive risk management. As a result, enhancing both workplace safety and operational resilience.

Reducing Unplanned Downtime

Unplanned outages are every facility manager’s nightmare. A single unexpected shutdown is capable of disrupting production schedules, delaying customer commitments and impacting revenue. However, electrical testing provides critical insight into the condition of equipment, enabling teams to plan repairs before failure occurs. Instead of scrambling to recover ROM sudden failures, managers can schedule interventions during planned downtime, reducing costly disruptions and maintaining smooth operations.

Ensuring Compliance & Accountability

In the modern world, compliance is a critical responsibility. Regulatory bodies such as NFPA, OSHA, IEC and IEEE establish stringent standards for the inspection and testing of electrical systems, and for good reason. They are designed to protect people, property and businesses. Therefore, regular electrical testing ensures your facility is not only aligned with these requirements but also demonstrates a culture of safety and accountability.

Extending Equipment Lifespan

Electrical assets represent some of the most significant investments within any facility and protecting them should be a top priority. Just as routine oil changes extend the life of an engine, preventive electrical testing serves as essential maintenance for critical systems. They ensure systems continue to perform safely and efficiently over time. Without this proactive care, hidden issues can quietly erode performance and accelerate wear, leading to costly breakdowns or the premature replacement of expensive equipment.

Through regular testing, facility managers can uncover conditions such as voltage imbalances, harmonic distortion, insulation degradation, or component fatigue. All of which, if left unaddressed, gradually shorten the lifespan of motors, switchgear, transformers, and distribution networks. Furthermore, addressing these issues early not only prevents avoidable failures but also ensures equipment operates within optimal parameters, reducing stress on components and improving overall efficiency.

Stay Ahead Of Issues With Electrical Testing

Electrical testing is more than just a compliance requirement. It’s a strategic investment in safety, reliability and efficiency. By proactively identifying hidden faults, reducing unplanned downtime and extending the lifespan of valuable assets, preventative testing helps businesses protect both people and property. Additionally, in today’s competitive environment, taking a reactive approach is no longer enough, facilities that prioritise testing position themselves for long-term success and peace of mind.

If you’re looking for professional electrical testing services in Devizes, contact Circuit Electrical today. Our team provides thorough, standards-compliant testing to keep your systems safe, efficient and fully operational.